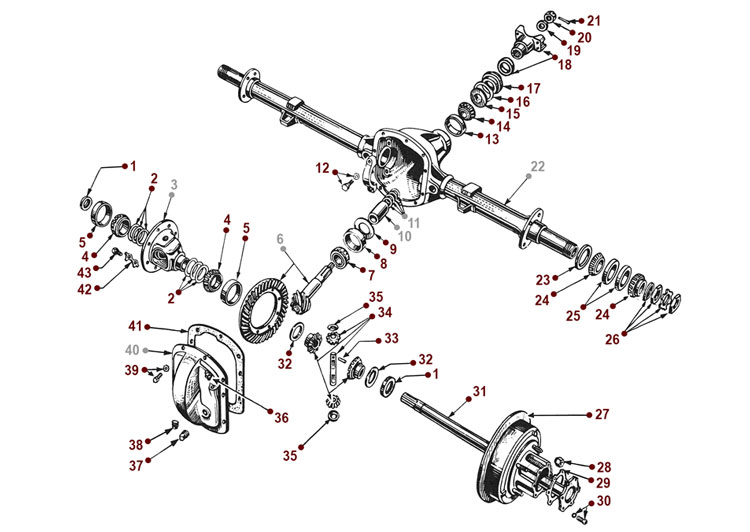

Dana 27 Rear Axle Tech and Troubleshooting - MB

Dana 27 rear axle illustration shown for reference only - click here to shop for these parts by interactive diagram

Looking for Dana 27 Rear Axle parts for your vintage Willys or Jeep? Search Axle by Category or by Diagram

Removing Rear Axle Assembly

Raise the rear of the vehicle with a hoist and safely support the frame ahead of the rear springs. Remove the wheels and disconnect the propeller shaft at the rear universal joint companion flange. Disconnect the shock absorbers at the axle mounting pads. Disconnect the brake hydraulic hose at the tee just forward of the tubing clipped to the axle. Support the axle assembly on a jack, remove the spring to axle U-bolt clips and slide the as-sembly from underneath the vehicle. (N-2, p198)

Full Floating Axle Shaft Removal

To remove the full-floating axle shaft, it is not necessary to jack up the rear wheel. Removal procedure:

• Remove the six screws holding the driving flange to the wheel hub.

• Screw two flange screws into the threaded holes in the axle flange to loosen the shaft. Remove the shaft.

• If shaft is broken, remove the outer piece of the shaft. Then, loop a piece of stiff wire over the piece of shaft remaining inside the housing. Pull the wire to bind the loop on the shaft piece and remove it.

• Replace the shaft in reverse order. Install the shaft carefully so the inner oil seal at the differential is not knocked out. (N-3, p198)

To remove axle shafts from an axle follow the sequence below:

• Jack up the wheel and remove the hub cap.

• Remove the axle shaft nut.

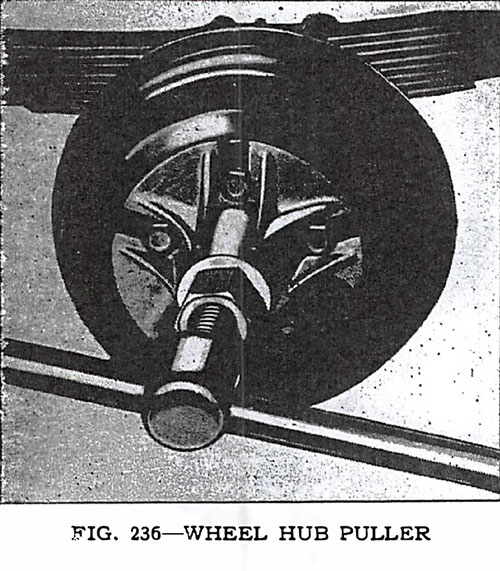

• Use a puller (Tool C-319, Fig. 236), to remove the wheel hub.

• Remove the screws attaching the brake dust shield, grease and bearing retainers, and brake assembly. Remove the shield and retainer.

• Pull out the axle shaft with Tool C-637 using care not to lose the adjusting shims. Should an axle shaft be broken, the inner end can usually be drawn out of the housing with a wire loop after the outer oil seal is removed. However, if the broken end is less than 8" [20,3 cm.] long it will usually be necessary to remove the differential. (N-4, p198)

Rear Wheel Noise

Looseness of the rear axle shaft nut on semi-floating rear axles may produce a clicking or creaking noise. This noise can usually be stopped by torquing the nut 150 to 175 lb-ft.

*Excerpt from the click here to shop for these parts by interactive diagram

RELATED VIDEOS: